3D printing technology is widely used in different industries – from medical to aerospace. The construction industry is not an exclusion, though printed houses can be considered a new word in the building.

The working principle of 3D printers is rather simple – a special machine prints predefined objects in a layer-by-layer fashion. As a result, different objects appear – from tools to houses. The material used varies according to what you want to print.

3D Printing in Construction: Is It Safe?

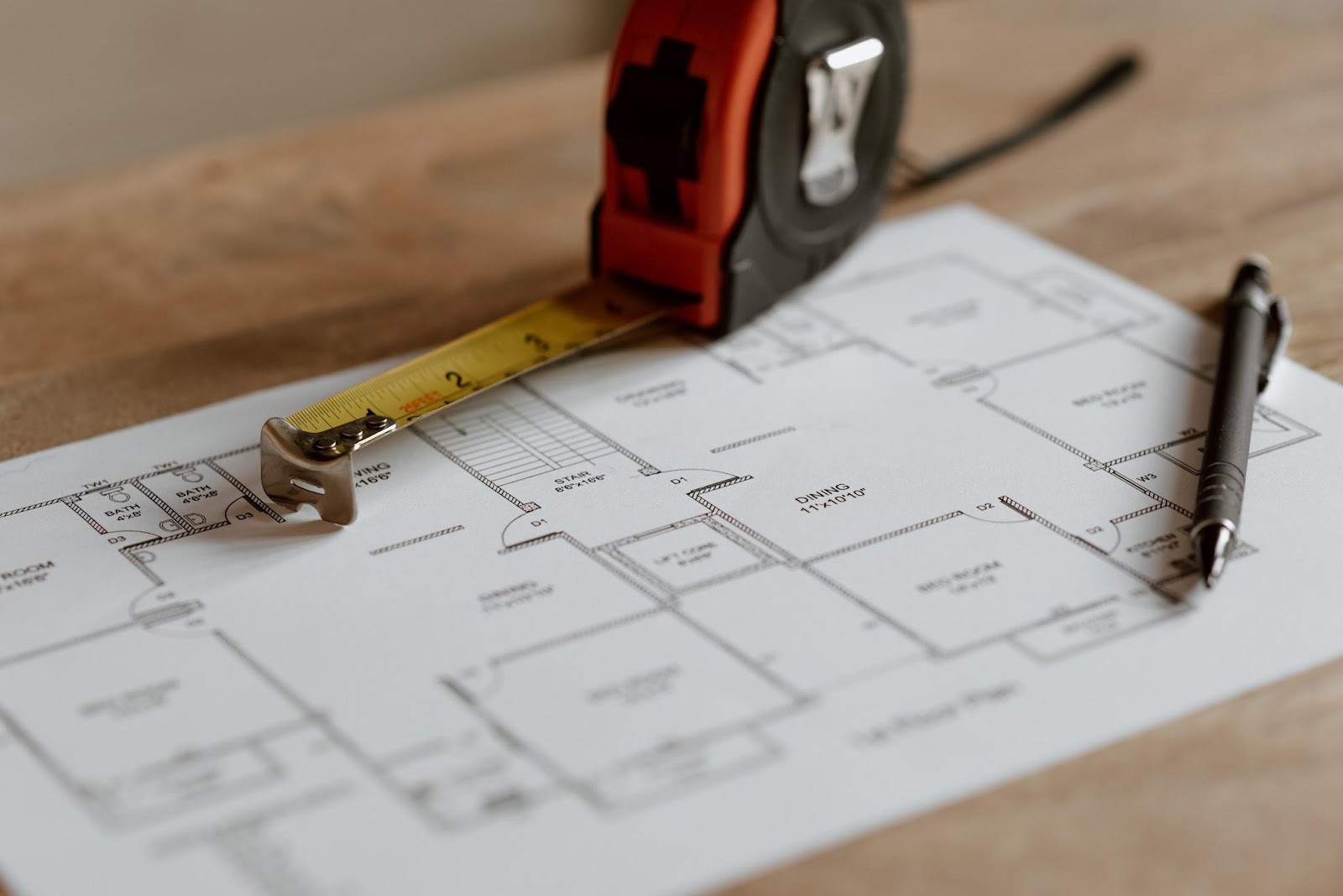

In the construction industry, for building purposes, 3D printers use concrete – one of the most widely used materials. It is not a secret that concrete is rather safe and sustainable. It consists of cement, sand, gravel, and water. One of its numerous advantages is that, unlike other building materials, for example, wood, it is not easily ignitable. Besides, concrete used by 3D printers has to necessarily meet safety standards and conform with local state laws and regulations. For safety reasons, during the process of 3D printing of walls, rebar reinforcement is used like in any other concrete slab. It is done to make the construction firmly established. One more evidence of 3D printing being safe for construction purposes is that concrete mixture extrude is configured automatically to gain the exact accuracy of actions. You may contact a construction accident lawyer in New York if you were injured even on a 3D Printing Construction site.

Why People Use 3D Printing in Construction Industry

Like any other industry, construction engineering is continuously evolving. As a result, it tends to use new technologies to make the building process safer, cheaper, and faster. 3D printing in the construction industry can be a good solution for this purpose. It helps to settle many problems beginning with utilizing construction waste to cutting to a minimum the percentage of human errors. A substantial advantage of 3D printing in construction is the possibility to erect a building of any design from the ground up using this technology. The clear benefit of 3D printing construction lies in the fact that it usually takes only a couple of days and a small amount of personnel to build a house. It is especially valuable in changeable climates with a limited number of sunny days.

The Challenges of 3D Printed Constructions

Like any technology, 3D printing has its disadvantages. The majority of them are connected with the cost. The equipment involving high-powered lasers and its transportation to the building site can be rather expensive. Building materials are a separate item of expenses. Another difficulty is finding qualified workers familiar with 3D printing construction technology. 3D printing in the construction industry is a comparatively new technology and it can be a challenge to hire builders trained to design computer models and make the exact mix of ingredients for proper consistency of concrete. Unfavorable weather conditions can also become an embarrassment for the equipment and therefore the house printing process.

Concrete Walls vs. Wood Walls: Which Are Safest?

Wood has been a popular constructing material for many centuries due to its thermal, acoustic, electrical, aesthetic, and working properties. Despite their numerous advantages, wooden walls have several serious drawbacks. They can easily ignite and hardly withstand heavy weather – in a severe storm they can be seriously damaged. As a result, the whole building can be ruined. Besides, wooden walls are hygroscopic and therefore prone to mold fungi. Because of its organic origin, it is a nutritional product for some wood boring insects. Wood is especially vulnerable to such pests as powder post beetles, marine borers, carpenter ants. Printed 3D concrete walls can be a good alternative to wooden ones. Being made of reliable material, they are rather solid, not combustible, and resistant to aging issues. Among other advantages of concrete, its temperature and noise control, green construction and economic value can be mentioned.

What about Construction Liability?

For now, laws regulating 3D printing are not that numerous. No matter how a house was built – by hand or by the printer – it must conform to the safety regulations. The construction company responsible for the building should be held liable for any errors whether concerning improper materials, design of the house, or its improper assembly.

There exist various building technologies the choice of which is determined by many factors. The compelling advantages of using 3D printing in construction are safety, and time and cost-saving. It may be stated with assurance that 3D printing construction is the thing of the future.