3D printers are very affordable, which means something like a snowflake or toy can be printed at home. It could also be used for prototyping, modeling airplane hobby tableaus, or for all kinds of DIYs. A 3D printer typically takes the place of a home printer next to it and sometimes its owner will think about printing something. How about the Eiffel Tower, the Arc de Triomphe, and a few other iconic Parisian landmarks to spoil your little sister?

The increasing popularity of 3D printers is no surprise. They’re affordable, convenient to use and highly versatile. One of the most popular trends this year is that more and more printers are now at home. This might seem like a nightmare to some, but they’re working tools and assistants for many and will continue to be! They can also be toys and training complexes for kids these days.

The article may be for complete beginners but you’ll find it impossible to find content without knowing the basics. You should first ask what type of 3D printer you have. The printing technology varies from machine to machine. Most hobbyist 3D printers currently use a technology known as FDM, which is a more common abbreviation of Fused Deposition Modeling or also sometimes referred to as Plastic Jet Printing. The printing technology is really simple and straightforward: layers of plastic (rarely of another material) are superimposed on each other to form the shape that you have modeled. That is, the product is formed of many horizontal sections. These are made out of plastic that’s extruded from a hot nozzle and then quickly solidifies after it’s formed.

Additionally, laser printers harden a material as it interacts with a laser, creating a three-dimensional shape. These printers offer sophisticated detail and precision.

People who do their own printing and design at home may use colored plastic. This material is usually sold in the form of threads on spools, rarely in short lengths. However, as we recall from chemistry class, not all materials are the same and they each possess their own properties like strength, fragility, transparency etc. Most people call it ABS filament or PLA filament. But these aren’t the only names.

ABS plastic is strong and durable, it does not break at folds or cracks. The ABS plastic polymer is a mix of acrylonitrile (up to 35%), butadiene (up to 30%), and styrene (up to 60%). The safety and environmental-friendliness of this material make it a great choice for toys. However, it becomes brittle when exposed to the weather (to the sun and frost) so clean storage is necessary.

PLA is a type of polyester that’s less resilient than ABS. It’s also completely eco-friendly and degradable. You can produce a type of polymer called PLA that is produced from corn or sugarcane. This type of plastic has good friction and will hold its shape better which is ideal if you are building any kind of moving parts.

The ABS is more for professionals and the PLA is more for amateur photographers.

Make sure you have the right filament diameter and spool size to match the specs of your printer.

• Printable area – 3D printing takes a lot of time and can be pretty expensive. The more you pay, the better the quality.

• The print speed is an important parameter in determining how quickly the molten filament will be released. (mm per second). Speed may not always measure up but printers with high print resolution are often worth rejoicing about. The speed of your 3D printer is affected by different factors, such as the materials you use and the structure that you create.

• Layer resolution – Achieving different results for art print relies wholly on the layer thickness. With a high resolution, the relief will be almost imperceptible and you make make a smooth product at low resolution with thicker layers. 3D printers typically give users the option to set the level of detail they want in the model.

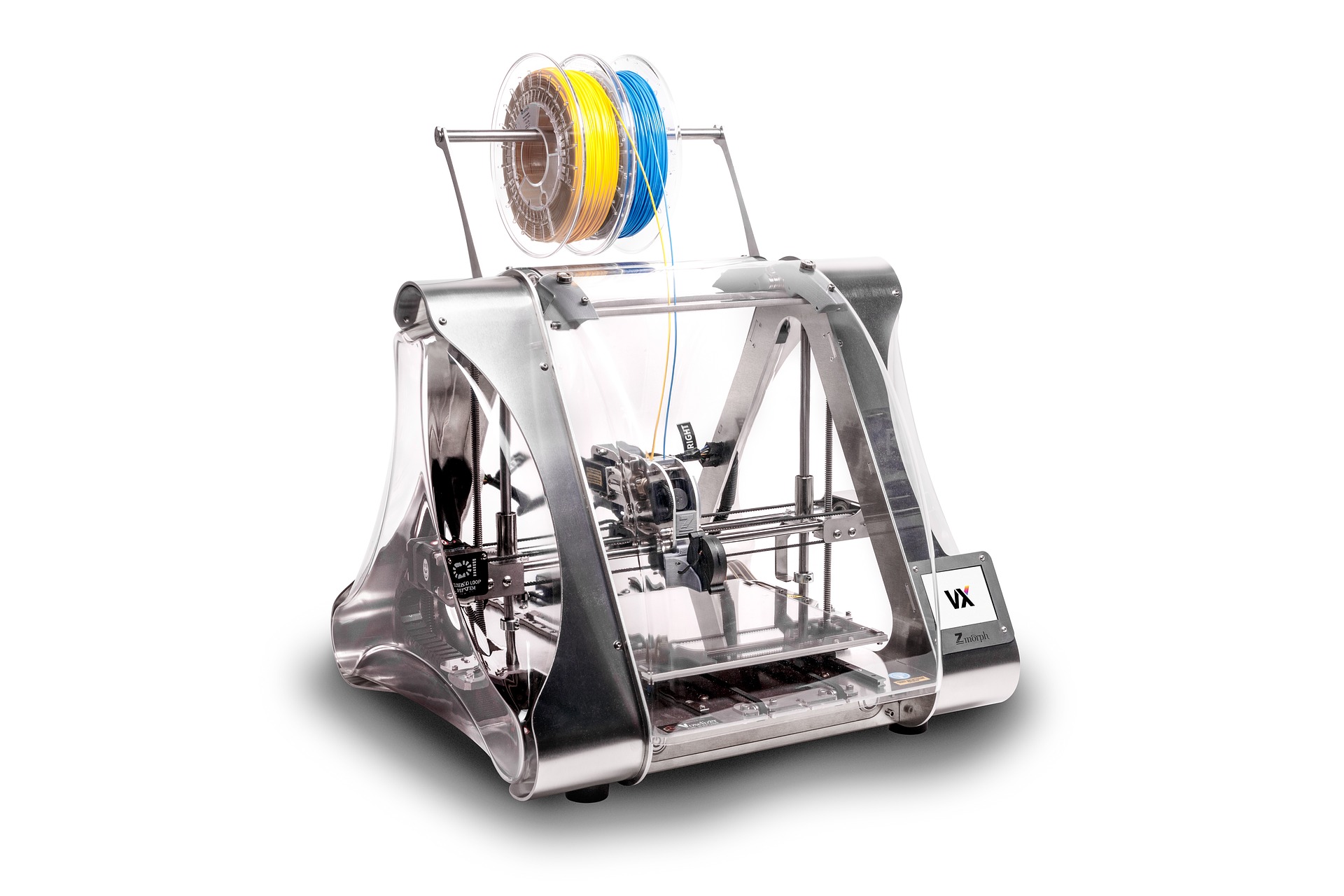

• Extruder – the crucial element that heats and releases the material. The material is melted and then extruded from it (fed to the print head). the extruder includes a heater (in normal models). If the printer has one extruder, then printing is pretty monotonous – one color at a time. But two or more extruders allow you to combine different colors and materials. Printers with two nozzles for one extruder are rare and expensive – but when you’re at home, they become an unnecessary option.

• Support for memory devices – Printers are equipped to support memory cards, USBs, smartphones, and Wi-Fi devices. One of the great benefits of 3D printing is not its ability to make physical models in a cost-effective manner. It is the ability to use a different set of parameters, or starting point for a model, without recreating it from scratch.

• 3D printer software usually comes with the hardware itself. Cosnta has always been around to help 3D printers. It can process STL file formats and transfer all the necessary parameters for a successful print. However, you might want to consider that 3D modeling requires specialized software like Sketchup, Autodesk Inventors Fusion, etc. It is these programs that will help you design the model and generate the STL file.

• Options – Aesthetics, the keyboard, material recognition etc. are matters of personal preference. However, all these options affect the price you end up paying for your device.

What do you need to decide on before ordering your 3D printer?

• Budget. When it comes to 3D printers, $ 150 can buy you an entry-level machine with limited features. More advanced options come with a higher price tag and may need additional consumables. 3D printers can be pretty expensive, so it’s important to choose a model that suits your needs. Keep in mind that some 3D printer models may lack certain functions to suit your unique needs as a business.

• Required materials and their properties – ask the price of materials and consumables, make a list and calculate the amount of threads that you need. If it is a commercial project, be aware that the delivery process will take some time. Be sure to check if the selected printer supports the required types of plastics.

• Multicolor printing – if you need multiple colors, you need a multi-extruder printer, which is a different price point.

• Your projects. What projects do you have going on? How busy will your printer be? What materials do you need?

• Different printers do different things. Some printers, like the Dotmatrix Printer, are better for printing logos and short messages while you’ll need a Pigment Printer if you need to print on large banners. If you don’t want to buy a toy or “baby” a child then it is better not to turn to either despite what they might otherwise want. The best course of action in this case would be for you to invest in an affordable printer with a small working volume instead.

• Place for the printer – a table or any other surface that’s flat. However, if this is an apartment and not a garage, then we recommend that you don’t choose completely sealed spaces. Working with hot materials causes them to get a certain smell, which can be unpleasant and disrupt the people in the room. For this reason, you need to get a good ventilation system in place before starting work.

• If you want to know how the kids of tomorrow will celebrate Christmas, head over to my store CX, buy a cup of coffee and 3D print your own present. You’ll need to familiarize yourself with the technique, software, and memory cards. But it’s not difficult to get comfortable with the technology and after just a short time you’ll be an expert!

• Who else will use the 3D printer. If your friend, colleague, sibling or type of “peer” agrees to go in with you on a printer, it is ok and helpful for the both of you. That means you will share responsibility for paying for and maintaining the product. If you are having troubles with your computer, it’s best to go to the store with your son or daughter and choose a model that’s more stable and reliable.

• Be prepared to handle models. Unfortunately no one’s perfect, even time can’t be. And this is evident with the file you’re given to work with. Ranging from knives to scissors of different stripes, you’ll have to use all your skills and knowledge, as well as making executive decisions in order to create that figurine of perfection. You?ll need to remove any excess thread, nodules, or protrusions before you apply the product.